The companies will operate the co-production process by using KBR's PURIFIER ammonia process and JM's methanol process

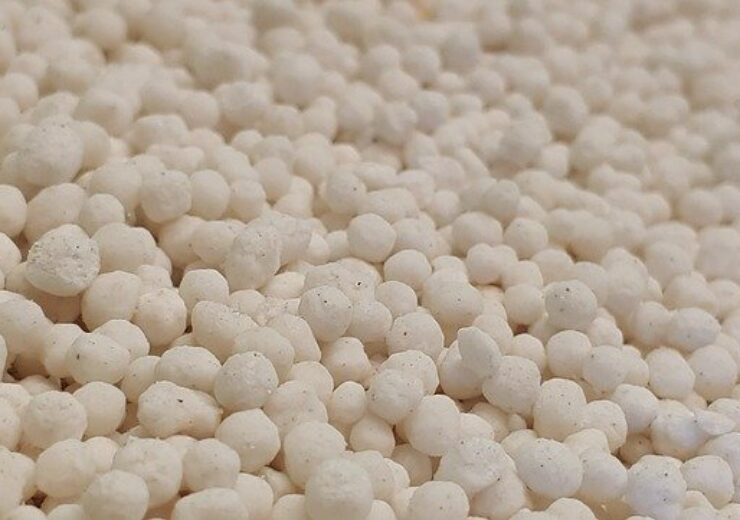

Ammonia is mainly used in the production of urea for fertilizer. (Credit: Samuel Faber from Pixabay)

KBR has entered into an alliance agreement with Johnson Matthey (JM) to licence an advanced ammonia-methanol co-production process technology.

The companies will run the co-production process by using KBR’s advanced PURIFIER ammonia process and JM’s methanol process.

KBR has licenced, engineered or constructed over 244 ammonia plants across the world from 1960. JM has been offering technology and catalysts for 45 years and has licenced more than 100 grassroots methanol plants.

KBR technology solutions president Doug Kelly said: “I am excited to announce the alliance agreement combining market-leading technologies from KBR and JM into a new offering for our clients.”

Ammonia is mainly used in the production of urea for fertiliser, while methanol and its derivative products are generally suitable for the production of formaldehyde, acrylic plastic, synthetic fabrics, adhesives, paints, and other products in pharmaceuticals and agrichemicals.

The co-production of methanol and ammonia in a single facility to provide multiple benefits

The co-production of methanol and ammonia in a single plant is said to offer multiple benefits, including reduced capital expenditures (CAPEX) and lower operating expenses (OPEX).

Both KBR and JM co-production process will help maximise the savings in CAPEX and OPEX while delivering enhanced levels of safety and flexibility.

Johnson Matthey managing director John Gordon said: “Methanol and ammonia hold great promise for continued energy and fuels transition to a greener world.

“This strategic agreement is a powerful combination that provides our customers with a comprehensive solution for enhanced asset optimization, cost savings and reduced environmental impact.”

In July this year, Cooperative Producers (CPI) partnered with Gavilon Fertilizer to build a new liquid fertiliser plant in Hastings, Nebraska.